Experience Expert CNC Turning Services for Metal Parts Manufacturing

Choose Great CNC for exceptional CNC turning services, as we are the leading CNC turned parts provider in China.

Receive top-notch custom CNC turning parts with efficient production, quick delivery, and affordable prices.

With more than two decades of expertise in CNC machining and CNC turned parts production, Great CNC offers the finest CNC lathe services and tailored CNC turning parts solutions.

- Precision Tolerance (as low as ±0.005)

- ISO 9001:2015 Accredited

- Swift Production & Delivery

- Global Shipping

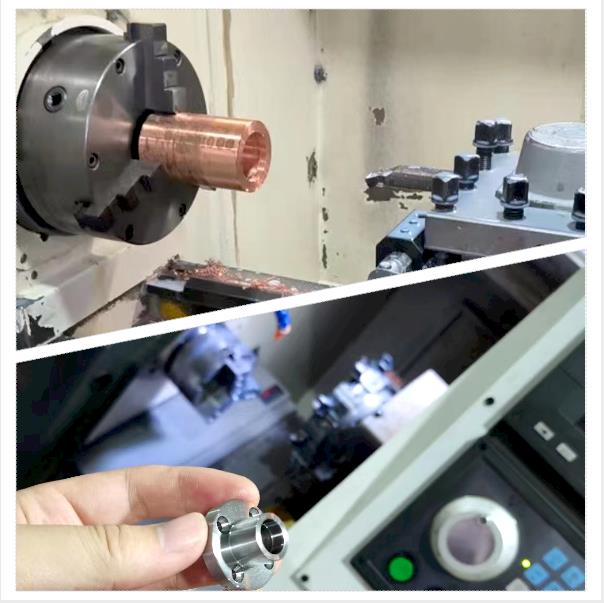

CNC Turning Part Cases & Product Gallery

We specialize in creating custom parts for clients using a variety of plastic and metal materials, catering to a wide range of needs, from rapid prototyping and low-volume production to large-scale manufacturing orders.

Top Turning Service Supplier In China

Top-Quality Facilities:

Great CNC uses advanced CNC turning machines for high-quality parts. Our turning centers can handle complex tasks for various industries.

Experienced Team:

Great CNC is a leading CNC turning parts manufacturer with over 13 years of experience. Our skilled team ensures high-quality parts and quick turnaround times.

Certified Excellence:

Great CNC is ISO 9001:2015 certified, ensuring a commitment to quality. Our QC and QA teams monitor the entire turning process for the best results.

What are the advantages of CNC turning?

CNC turning is an accurate, subtractive manufacturing process executed by CNC turning machines. Prior to processing, workpiece and cutting tool movements are preprogrammed. It offers 8 key benefits:

- Operates at high speeds.

- Ideal for creating round, tubular, and cylindrical parts.

- Various CNC turning machines enable diverse customization options.

- Achieves a smooth surface finish.

- Demands less energy and effort.

- Offers numerous CNC turning center options.

- Provides efficient production.

- Applicable to a broad range of uses.

What Materials Can Use For CNC Turning?

Our CNC workshop can process a wide range of engineering materials such as plastics, metals, alloys, foam, and tooling boards. We offer standard CNC milling materials, with additional options available upon request.

| Materials | Specifications |

Aluminum Machining | A16061, A16063, A16082, A17075. Al2024, A15052, A380, etc. |

Stainless Steel Machining | 55201.55301.55303. SS304. 55316.55416. etc. |

| Steel Machining | Mild Steel. Carbon Steel. 4140. 4340. Q235, Q34513, 20#. 45#. etc. |

Brass Machining | C35600, C36000, C37700. C37000. C37100, C28000, C26000, C24000. C22000. etc. |

| Copper Machining | C11000, C12000, C12200, C10100, etc. |

| Iron Machining | 20#.45#. Q235. Q345. Q3458. 1214. 12L14. 1215. etc. |

Plastic Machining | POM, Peek, PMMA, ABS, Del rin, Nylon, PVC. PP, PC, etc |

Surface Finishes of Our CNC Turning Services

After milling, surface finishes are applied to alter the appearance, surface roughness, hardness, and chemical resistance of manufactured parts. Here are the prevalent surface finish types from DEK

As Machined

Polishing

Bead Blasted

Anodized

Electropolished

Black Oxide

Powder Coated

Spray Painting

CNC turning process

In addition to turning, a range of other machining operations can be carried out on a lathe. These include:

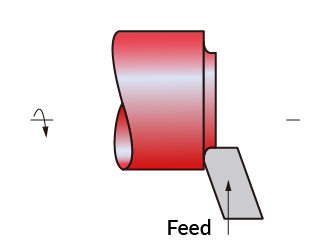

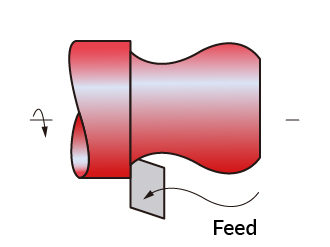

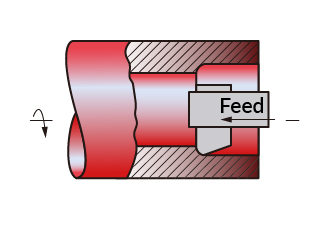

Facing

Creating a flat surface on the end of the rotating work by feeding the tool radially into it.

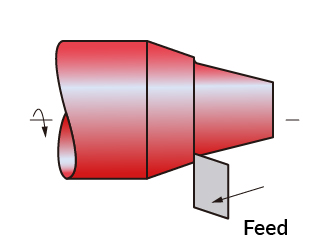

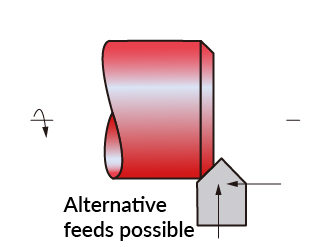

Taper Turning

Performing taper turning, which involves creating a constantly changing diameter on a cylindrical workpiece. This is often used to make conical shafts.

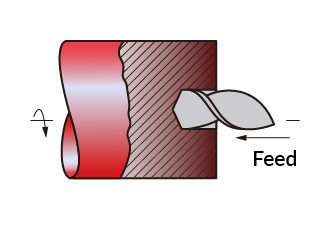

Contour Turning

Using the tool to follow a non-straight contour to produce a contoured form on the turned part, rather than feeding it in a straight line parallel to the axis of rotation as in turning.

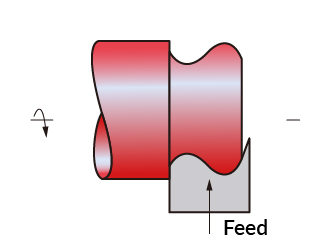

Form Turning

Plunging the tool radially into the work to impart a specific shape in an operation known as forming.

Chamfering

Cutting an angle on the corner of a cylinder using the cutting edge of the tool to produce a chamfer.

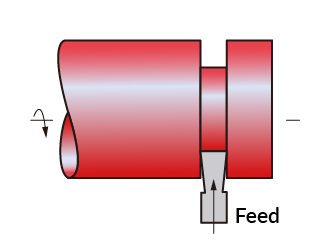

Cutoff

Radially feeding a tool into the spinning workpiece at a specific point along its length to remove the end is called parting.

Boring

A single-point tool moves linearly and parallel to the rotation axis within an existing hole's inner diameter.

Drilling

Drilling on a lathe involves feeding a drill into the spinning workpiece along its axis, while reaming follows a similar process.

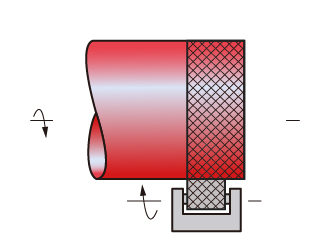

Knurling

This method is not machining as it doesn't cut material; it's a metal-forming technique that creates a consistent crosshatched pattern on the work surface.

What’s The Difference Between 3-Axis, 4-Axis & 5-Axis Machining?

10 Ways To Cut Stainless Steel