Custom CNC Milling Parts Manufacturer

At Great CNC, we provide exceptional CNC milling services to customers across the globe, delivering fast prototypes and production components with tight tolerances, superior accuracy, and a wide range of available materials.

Our CNC Machining capabilities include:

- 3-, 4-, and 5-axis CNC machining

- Over 50 material options to choose from

- Various surface finishes for customized appeal

- Personalized machined part designs

- Precise tolerances up to ± 0.05mm

Discover affordable, high-precision, and premium-quality custom CNC milling components at Great CNC, catering to the stringent requirements of diverse industries.

Custom Online CNC Milling Services

We specialize in creating custom parts for clients using a variety of plastic and metal materials, catering to a wide range of needs, from rapid prototyping and low-volume production to large-scale manufacturing orders.

Top-Quality CNC Milling Services at Great CNC

As a premier CNC Milling service provider, Great CNC has consistently delivered dependable CNC turning services across various industries for over 13 years. Leveraging advanced technologies and comprehensive expertise in CNC machining, Great CNC produces high-quality, cost-effective metal/plastic custom CNC milling components with guaranteed precision for your innovative projects.

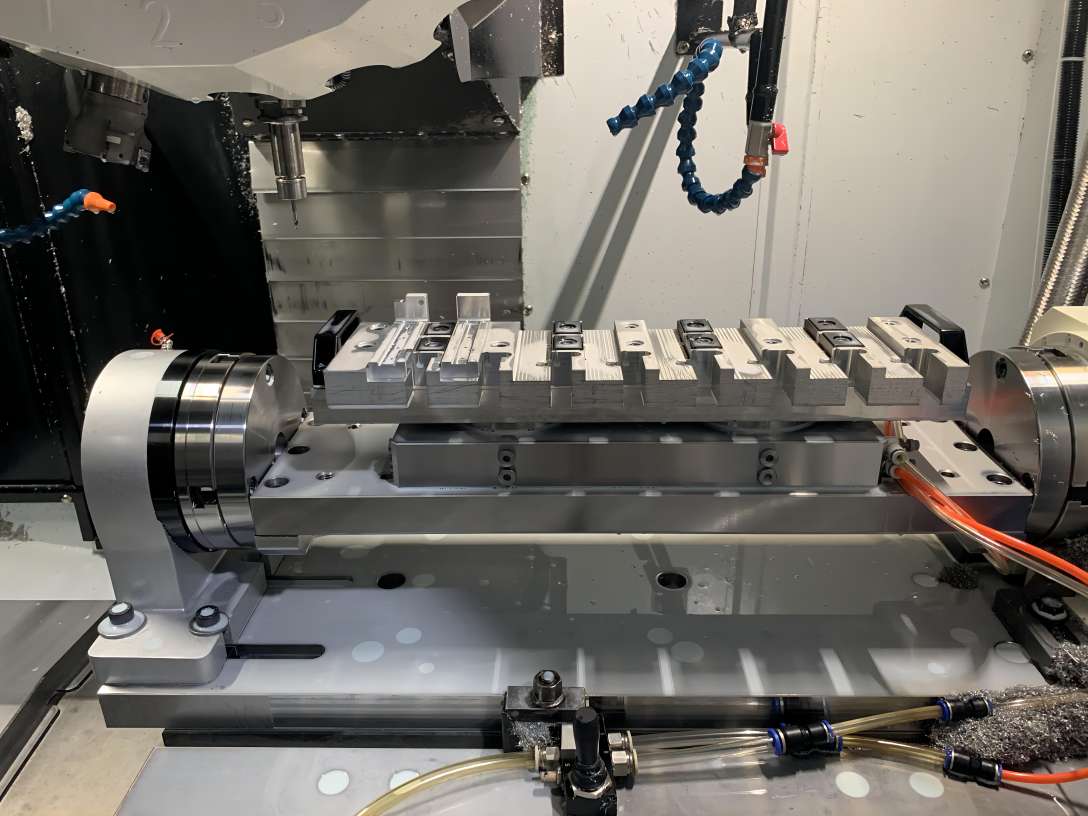

Our Exceptional CNC Milling Capabilities

As a top-tier CNC milling service manufacturer, Great CNC is equipped with state-of-the-art CNC milling machines and professional know-how to assist you in your one-of-a-kind projects.

- Experienced Engineers with 13 Years of Expertise

- ISO 9001 Certified Operational Standards

- Specialized CNC Milling Service Facility

- In-House Research and Development Departments

There are four distinct stages in the CNC milling process

CNC milling provides superior precision, accuracy, and production speeds. CNC milling machines are the systems utilized in these operations. The CNC milling process consists of four main steps:

1. CAD Model Creation Engineers design a 2D or 3D part model.

2. CNC Program Conversion The design is exported to a compatible format and converted into machine instructions using CAM software.

3. CNC Machine Setup The machine operator readies the machine and workpiece.

4. Milling Execution The machining program is initiated by the operator.

Precision 3 Axis and 5 Axis CNC Milling Services

Based on your specific needs, budget, and schedule, we will select the optimal milling method. Consult our experienced sales team to identify the perfect solution for your requirements.

3-axis CNC milling is a widely recognized technique for creating mechanical components, utilized across industries such as manufacturing, architecture, design, and art. This straightforward process involves a milling machine that operates on 3 axes (X, Y, and Z), removing material in three primary directions aligned with a flat surface. Ideal for uncomplicated designs without multi-surface requirements, 3-axis CNC milling offers a quick and cost-effective solution for producing simple parts.

5-axis milling incorporates the 4-axis milling axes plus an extra rotational axis, making it the most advanced CNC milling technology available today. It excels at creating intricate and precise parts for industries such as artificial bone production, aerospace, titanium components, oil and gas machinery, automotive molds, medical, architectural, and military. For complex internal designs or models with multiple irregular surfaces, 5-axis CNC milling machines are used to enhance accuracy and reduce both processing time and cost.

What Materials Can Use For CNC Milling?

Our CNC workshop can process a wide range of engineering materials such as plastics, metals, alloys, foam, and tooling boards. We offer standard CNC machining materials, with additional options available upon request.

| Materials | Specifications |

Aluminum Machining | A16061, A16063, A16082, A17075. Al2024, A15052, A380, etc. |

Stainless Steel Machining | 55201.55301.55303. SS304. 55316.55416. etc. |

| Steel Machining | Mild Steel. Carbon Steel. 4140. 4340. Q235, Q34513, 20#. 45#. etc. |

Brass Machining | C35600, C36000, C37700. C37000. C37100, C28000, C26000, C24000. C22000. etc. |

| Copper Machining | C11000, C12000, C12200, C10100, etc. |

| Iron Machining | 20#.45#. Q235. Q345. Q3458. 1214. 12L14. 1215. etc. |

Plastic Machining | POM, Peek, PMMA, ABS, Del rin, Nylon, PVC. PP, PC, etc |

Surface Finishes of Our CNC Miling Services

After milling, surface finishes are applied to alter the appearance, surface roughness, hardness, and chemical resistance of manufactured parts. Here are the prevalent surface finish types from Great CNC.

As Machined

Polishing

Bead Blasted

Anodized

Electropolished

Black Oxide

Powder Coated

Spray Painting

Standard Tolerance Of Our CNC Precision Milling Service

The table summarizes standard part tolerances. Custom tolerances up to 0.01mm can be requested. The tightest tolerance available is ±0.005 mm, depending on your needs.

| ISO 2768 Tolerance Standard | |||||||

| Tolerance Lever | Overall Dimension Rang | ||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

CNC Machining Service Applications

CNC machining services are known for their efficiency, precision, and affordability. They are used in various industries, including:

- 1. Automotive: CNC machines create car parts with high efficiency and accuracy, making the manufacturing process faster and more reliable.

- 2. Aerospace: Great CNC, a top CNC machining company in China, produces high-quality aircraft components and prototypes with tight tolerances and extreme precision.

- 3. Medical: CNC machines are used to make surgical instruments and medical devices like implants and prosthetics, offering quick turnaround and lower costs.

- 4. Consumer Goods: CNC machines can create complex shapes for electronics, phones, laptops, TVs, and other consumer products at high productivity and low cost.

- 5. Military: CNC machines produce reliable military parts for army equipment and aircraft. CNC machining is also popular in construction, transportation, new energy, telecommunications, and recreational industries.

What’s The Difference Between 3-Axis, 4-Axis & 5-Axis Machining?

10 Ways To Cut Stainless Steel