描述

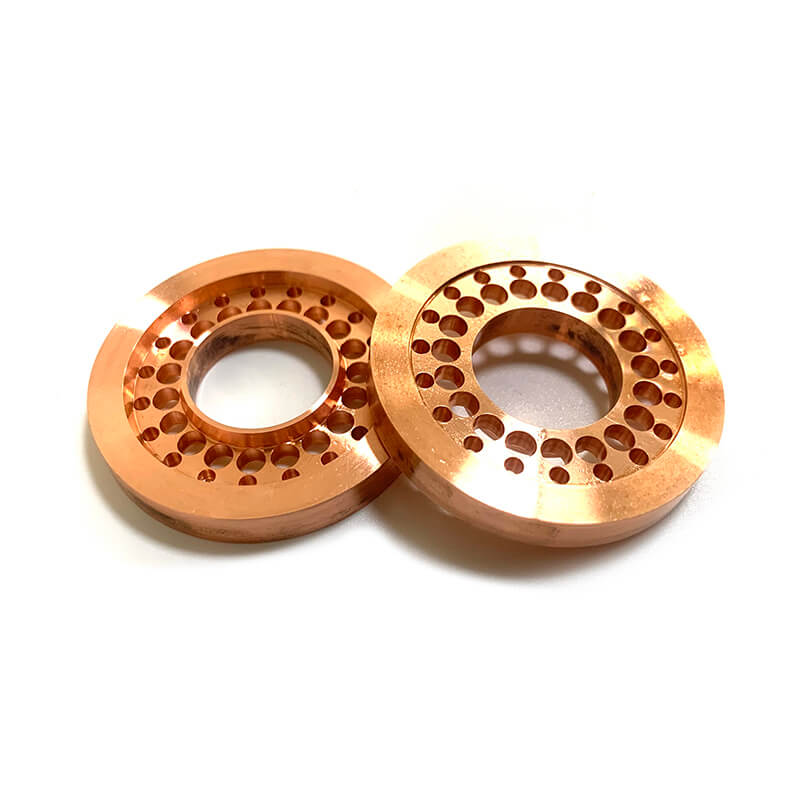

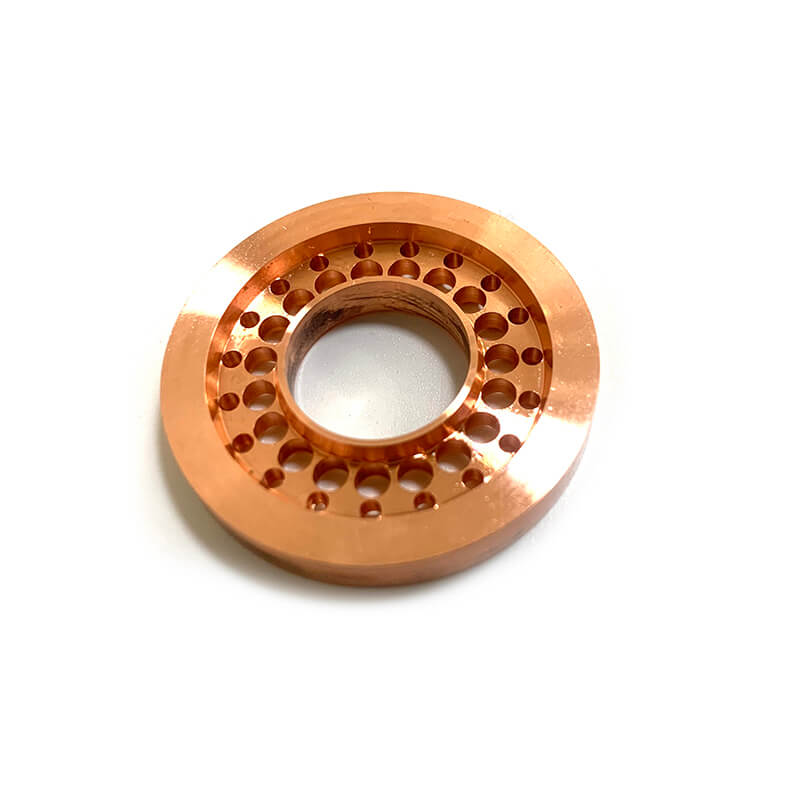

Product Material: Red Copper

Product Name: Customized Machining Copper Parts

| Materials | Red Copper | |

| Specification | Size | 46*46*8mm |

| Process | Machining, Grinding, Oxidation | |

| Hoze Size | ¢5 | |

| Accuracy | ±0.02mm | |

| Tolerance | ±0.02mm | |

| Surface Finish | Oxidation | |

Quality Assurance: 100% Inspection with Report

Advantages and Application

The CNC turning and milling composite parts manufactured this time are generator rotor parts specifically designed for aviation applications. These rotor parts play a critical role in the functioning of motors used in aviation. Each motor rotor comprises two of these specialized rotor parts.

To enhance the electrical conductivity of the motor rotor, red copper is the chosen material for manufacturing these parts. Red copper, also known as pure copper, is highly regarded for its excellent electrical conductivity, making it ideal for applications where electrical performance is crucial.

By utilizing CNC turning and milling processes, the generator rotor parts are precisely crafted to meet the stringent requirements of aviation applications. The combination of red copper material and advanced machining techniques ensures reliable and efficient performance in the motors used in aviation equipment.